We provide solutions for some of the world’s largest companies

CNC Tube Manipulation

Safety Devices offer advanced CNC tube manipulation capabilities, with multiple machines to ensure robust contingency. Our comprehensive services encompass stack bending and rolling, which combined with our calibration methods and experience, offers the ability to consistently achieve multiple bend radii on the same part. As specialists in CNC tube manipulation from 19 – 89mm, we can deliver high-quality tailored solutions to meet your specific project requirements.

CNC Tube Profiling

To compliment our tube manipulation capabilities, we also offer CNC tube profiling across multiple machines. We routinely profile tubular components prior to the bending process, and in exceptional cases have even profiled bent tubes where the design dictates.

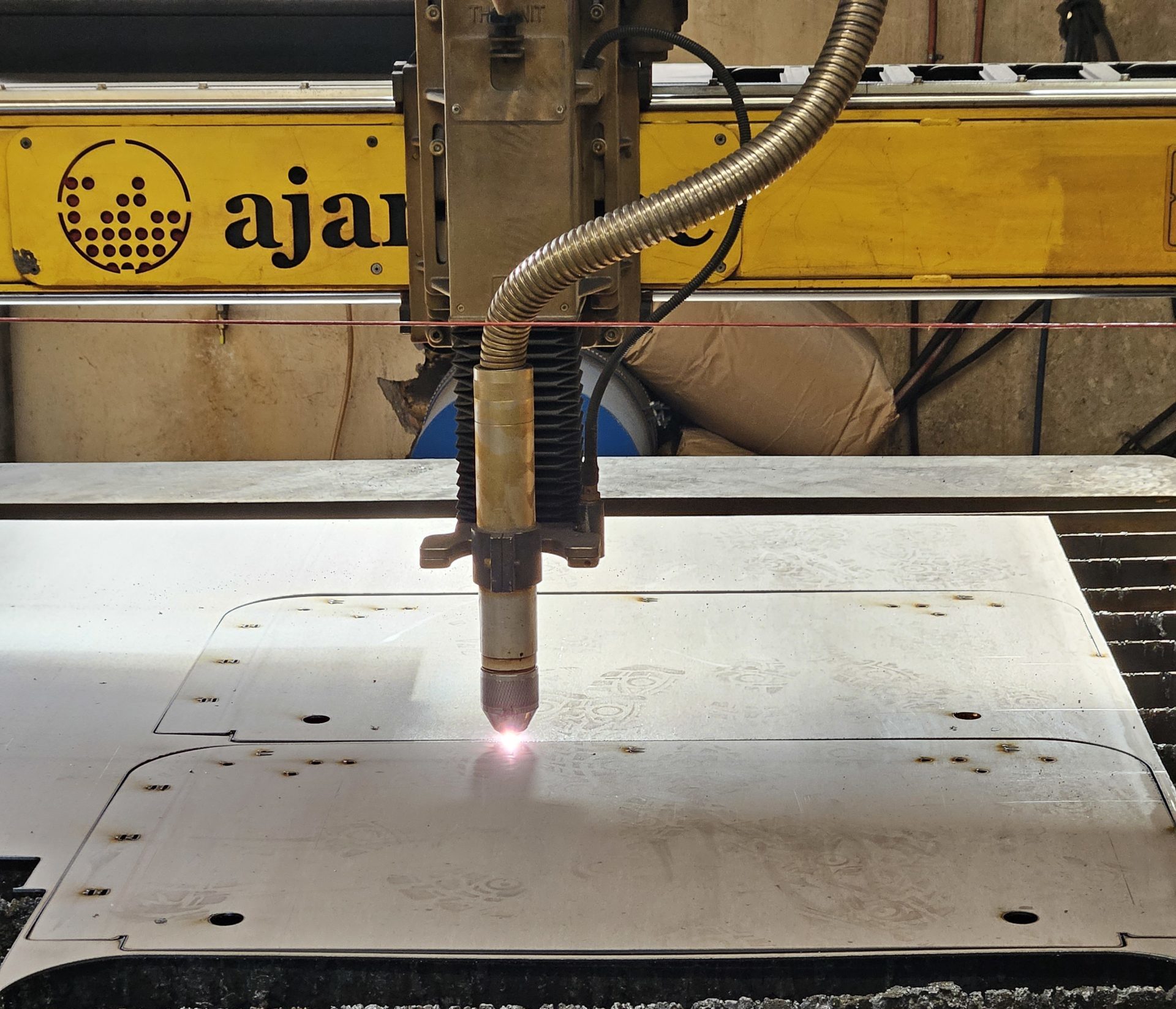

CNC Plate Cutting

We provide expert CNC plate cutting services on various materials, up to 20mm thick. Using advanced technologies, our CNC plate cutting capabilities allow us to meet your specific design needs, ensuring high-quality results for any project.

Plate Forming

With numerous in-house plate forming machines including press brakes and power presses, we are able to supply components to complex designs. To ensure conformity for high volume plate parts, our press tooling expertise allow us to conduct multiple operations to produce intricate finished items.

Manufacturing Compliance

With expertise in a broad array of internationally recognised standards, and ISO9001 as the backbone of our quality management system, we confidently ensure compliance through implementation of multiple manufacturing and assembly standards including:

• Provisional and Qualified Welding Procedure Specification (PWPS, WPS)

• ISO9606 Welder Certification

• ISO13920 General Tolerances for Welded Constructions

• ISO12944 Protective Paint Systems

• ISO8130 Coating Powders

• ISO9227 Neutral Salt Spray (NSS) Testing

CNC Machining

With a commitment to excellence in advanced CNC machining services, we offer our customers innovative solutions in milling, turning, and lathe operations, including 5-axis machining. Our precision CNC machining capabilities ensure we produce complex parts with exceptional accuracy and efficiency, from intricate designs to high-volume production runs.

Welding

Safety Devices’ comprehensive welding services are performed by our team of dedicated, certified welders, skilled in manual MIG, MAG and TIG processes. Our expertise ensures welds are carried out in accordance with the relevant Welding Procedure Specifications (WPS), tailored to meet the specific requirements of your projects.

Robot Welding Cell

Our dual MIG/MAG robot welding cell enables us to deliver consistent and precise welding solutions for a range of high-volume projects. Able to operate continuously, this advanced system is supported by our expert team of programmers and weld inspectors to ensure high quality and consistency in every production run.

Safety Devices is the world’s largest, most trusted and experienced roll-over protection designers and manufacturers with over 50 years of experience.

50+ Years

Worldwide solutions

Largest product range

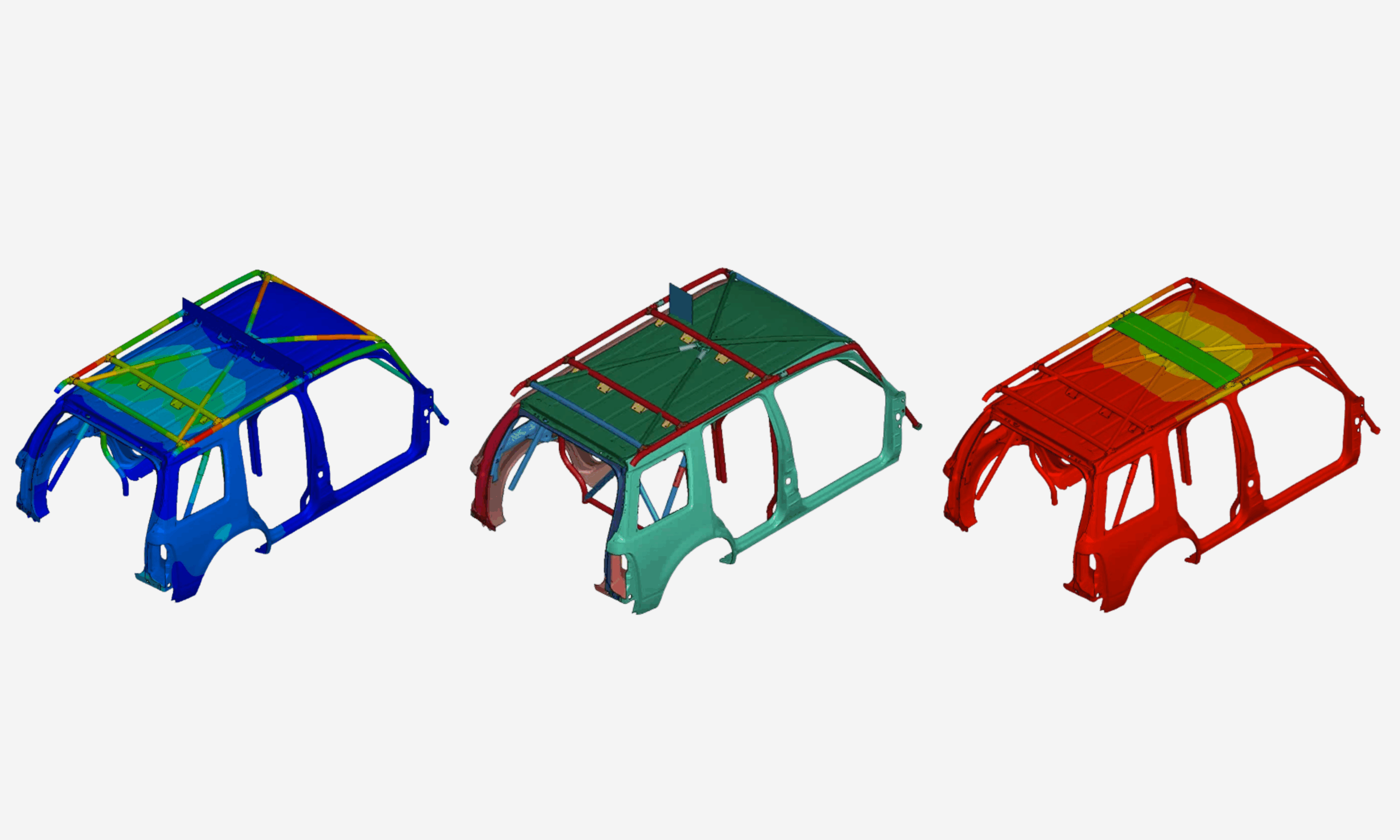

Design Excellence

Quality assurance

Advice & After Sales

FAQs

Do you have any technical drawings or data of the roll cage I want?

You can find detailed images and assembly drawings available on many of our product listings. If you require any additional information, please contact our sales team who may be able to assist you further.

Do Safety Devices offer roll cage installation?

Yes, we do offer on-site roll cage installations, however these are dependent on our workshop availability. For a quotation, please contact our sales team who can assist your further.

Who can I contact for technical advice on your products?

If you require technical support with any of our products, please contact our sales team who will be able to assist you further.

Can I install my own roll cage?

What type of padding should I use for 4×4 and off roading?

We recommend that all internal components of the roll cage be covered with padding, with particular emphasis on protecting high-impact areas, such as those above the shoulders and around the head.

Phone+44 (0)1638 713 606

Opening Hours09:00 – 17:00

Monday – Friday

Holborn Ave

Mildenhall

Suffolk

IP28 7AN

United Kingdom