We provide solutions for some of the world’s largest companies

In-house Design

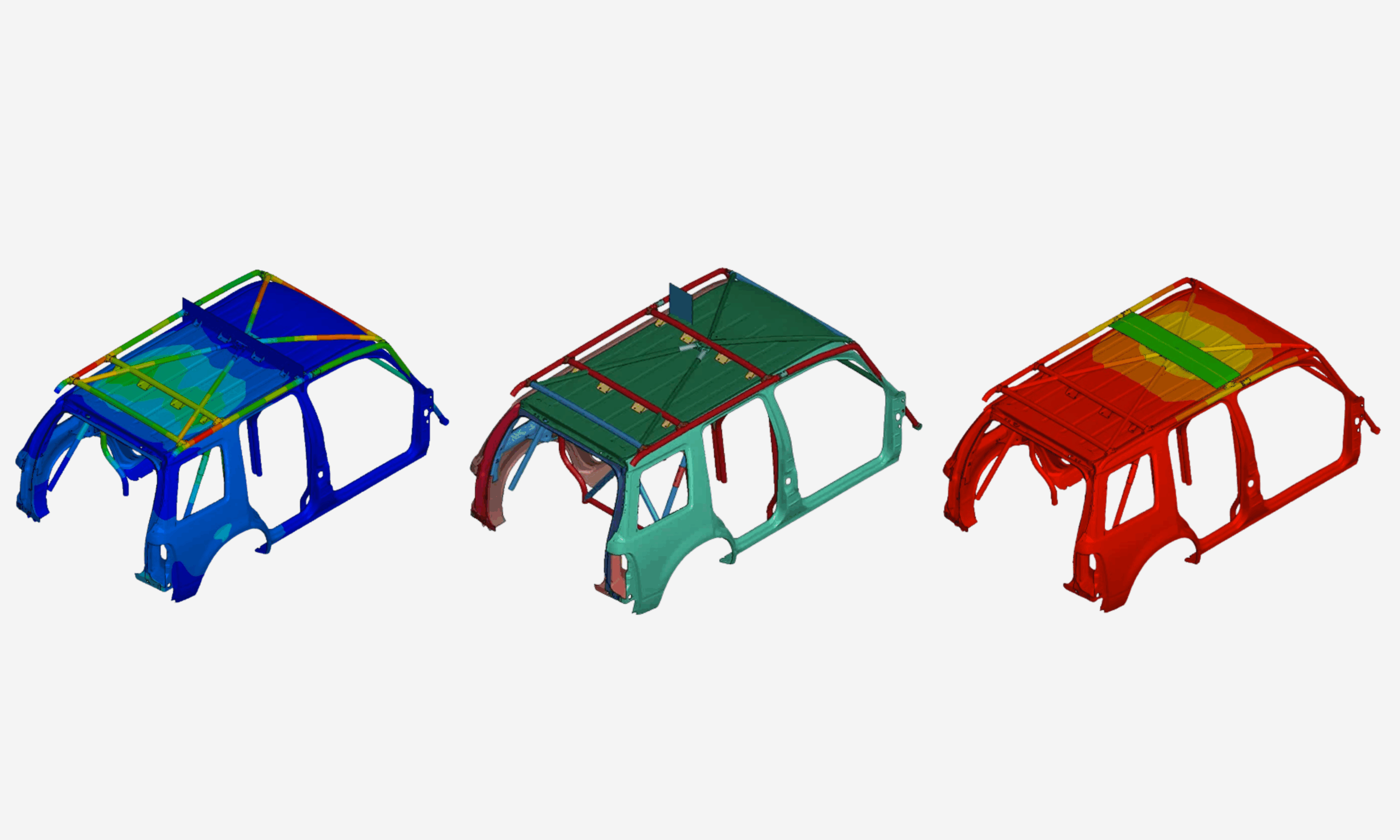

Safety Devices’ in-house design team consists of multiple permanent stations equipped with advanced computer-aided design and manufacturing software (CAD/CAM), including SolidWorks, TubeWorks and PowerInspect. We support our customers in formulating comprehensive design briefs through careful research, identifying specific requirements and conducting feasibility assessments. This iterative design process can include:

- Concept Generation

- Preliminary Design

- Detailed Design

- Production Implementation

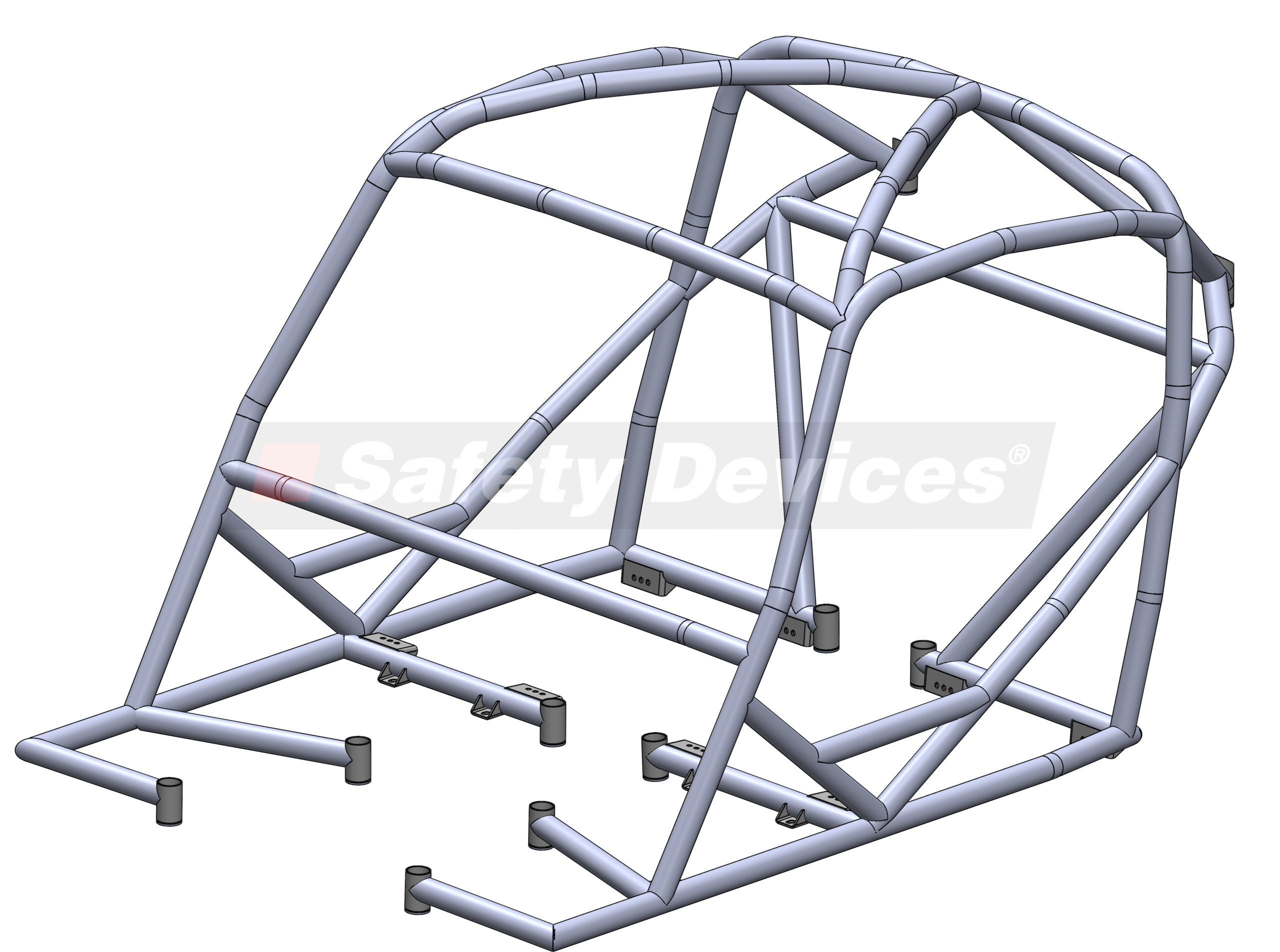

Our skilled and knowledgeable engineers routinely create, develop and optimise products accurately, providing our clients with access to a wealth of design techniques. Through 3D modelling, comprehensive measurement, assembly design, evaluation, data extraction and inspection we ensure the development of optimised products that meet our client’s needs.

Reverse Engineering

Product application, functionality and underlying principles are key considerations when undertaking reverse engineering. Through detailed analysis and evaluation of an existing component, we can expertly isolate individual manufacturing processes to establish key characteristics, enabling us to replicate or further enhance products.

Whether you are trying to emulate an original design for production, source a discontinued part or find a replacement for an obsolete OEM product (original equipment manufacturer), our designers are well versed in providing competent analysis and solutions.

Design for Manufacture

From the earliest stages of product design, we combine advanced software systems with our extensive knowledge to optimise manufacturing efficiency, through intuitive design and reduced complexity. Our ability to effectively understand different manufacturing techniques, materials and their limitations enables us to consider various design factors such as:

- Tolerance Definition

- Optimised Material Selection

- Compensations for Weld Distortion and Shrinkage

- Springback Allowance

- Fixture and Tooling Suitability

- Assembly Considerations

Our design for manufacture service encompasses all these elements to accelerate product manufacture, lower production costs and enhance overall quality for our customers.

Safety Devices is the world’s largest, most trusted and experienced roll-over protection designers and manufacturers with over 50 years of experience.

50+ Years

Worldwide solutions

Largest product range

Design Excellence

Quality assurance

Advice & After Sales

FAQs

Which quality standards do you employ?

We are renowned for the quality of our products using only the finest, traceable materials, offering proven capability to fabricate roll over protection in line with various industry standards. To ensure that our products meet the highest standards for a wide range of project needs, Safety Devices are ISO9001 certified.

What are your roll cages made of?

The majority of Safety Devices roll cages are manufactured from E355+N Cold Drawn Seamless Carbon Steel. On a number of our internationally homologated weld in roll cages, we also offer T45 as an alternative material. More exotic materials (Chromoly, 15CDV6, Titanium) can also be used in some applications providing regulations allow, however the material costs of these can be significantly higher than E355+N or T45.

What is a roll cage or ROPS?

A roll cage or ROPS (Roll Over Protection System) is an internal or external structure installed on a vehicle, designed to protect vehicle occupants by preserving survival space during a rollover incident.

Can I buy products directly from Safety Devices?

Yes, well sell directly to companies and other organisations within the Automotive, Fleet, Construction and Military sectors.

Where are Safety Devices products made?

All of our products are supplied through our development workshop and offices located in the United Kingdom, or our dedicated production facility operating out of Poland. These premises are wholly owned and operated by Safety Devices.

Phone+44 (0)1638 713 606

Opening Hours09:00 – 17:00

Monday – Friday

Holborn Ave

Mildenhall

Suffolk

IP28 7AN

United Kingdom