We provide solutions for some of the world’s largest companies

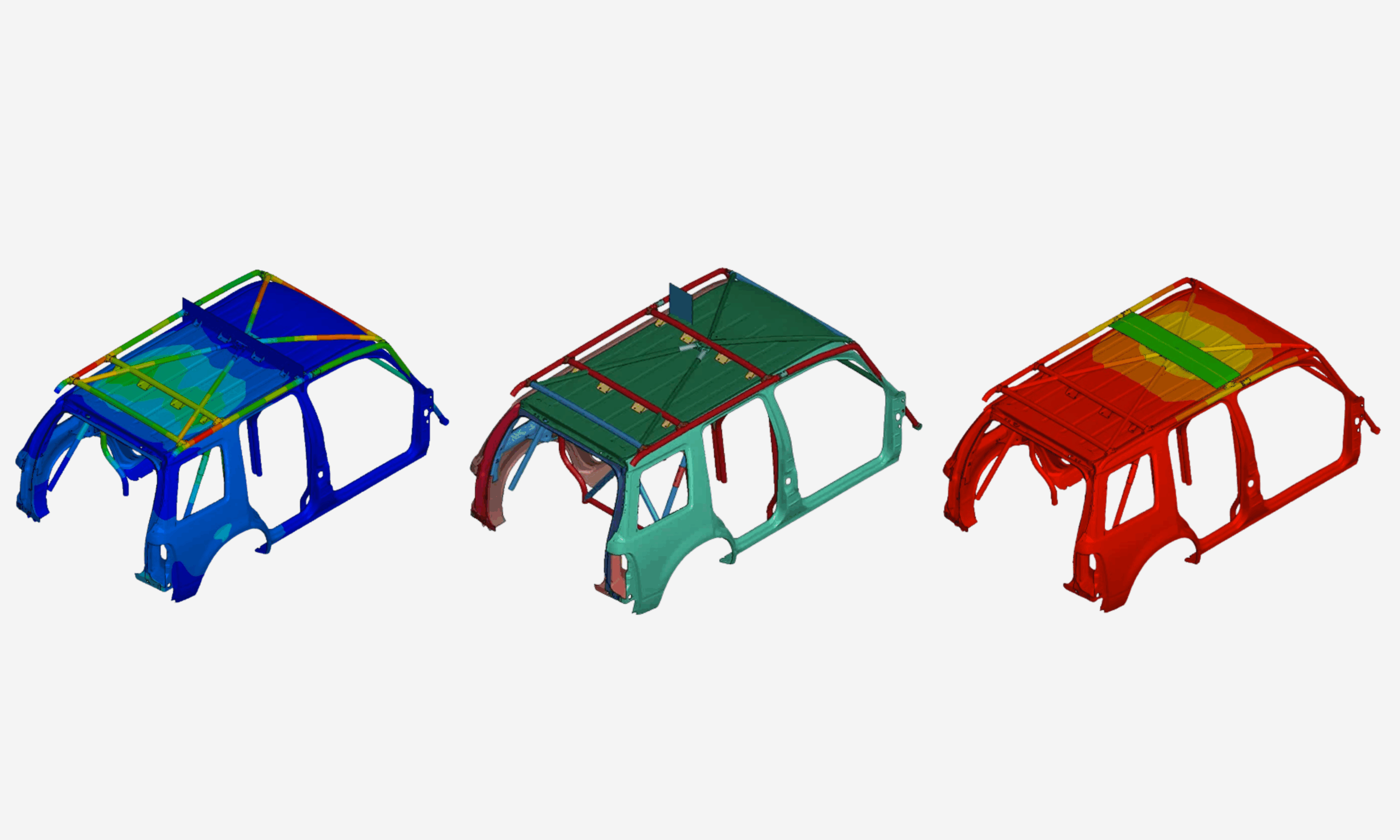

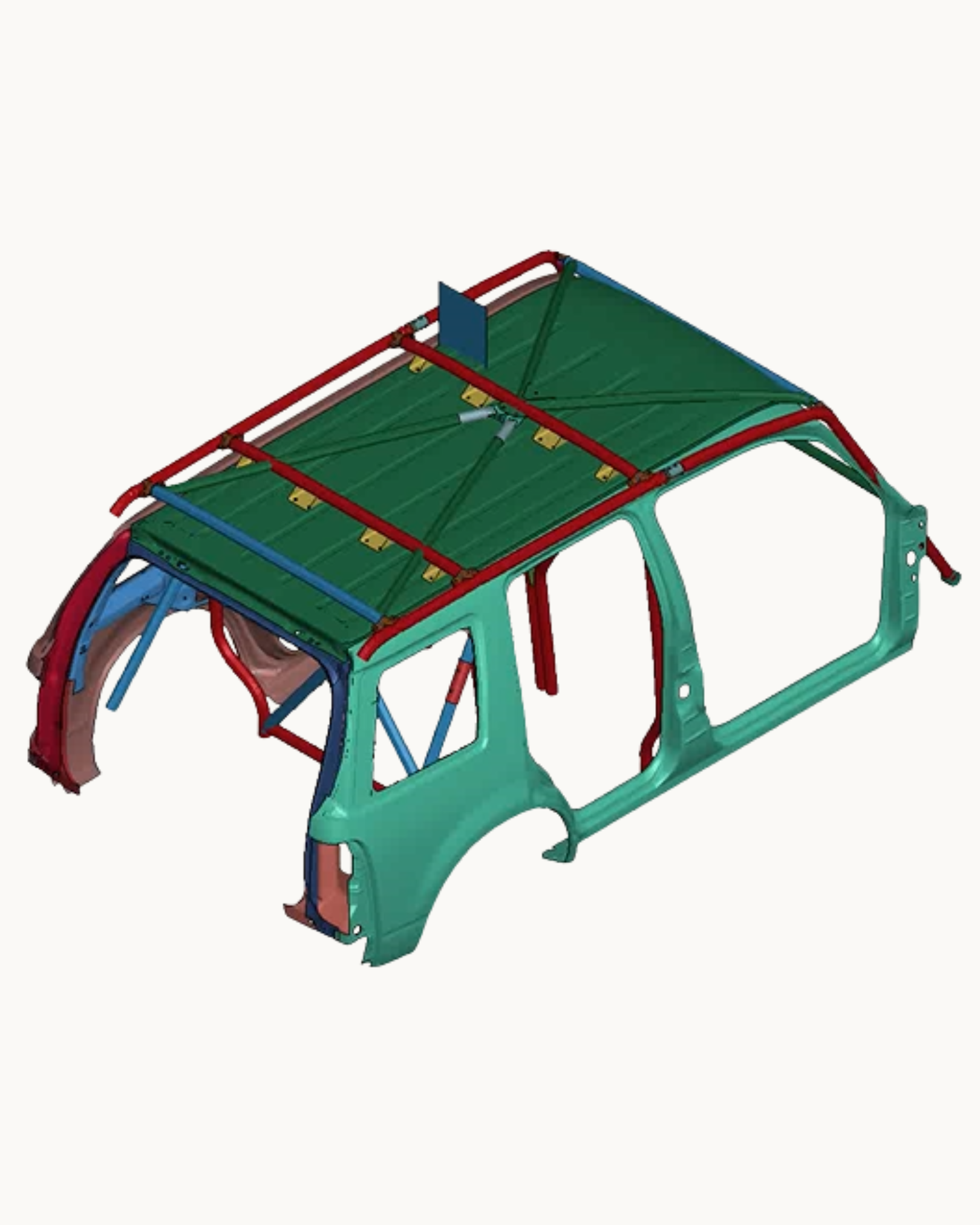

Finite Element Analysis

Alongside our wealth of experience, we routinely perform in-depth analysis utilising powerful LS-DYNA and Genesis software. This service allows us to deliver rapid and dynamic analyses, leading to a more refined, proven, and optimised solution.

Our complex analysis can include:

- Stress/Fatigue Analysis

- Kinematic Analysis

- Static & Dynamic Simulations

- Roll Over & Falling Object Protection Systems (ROPS/FOPS) Deformation

- Seatbelt Anchorage Testing

- Durability Assessment

- Frontal Impact/Crash Testing

Our expertise in FEA ensures appropriate boundary conditions, mesh density and considered use of beam versus shell elements, to provide the optimum balance between efficiency and accuracy. Having conducted numerous physical tests over the years, our analysis incorporates an extensive calibrated material library to establish correlation with physical material behaviour.

Physical Testing

Our physical verification processes include extensive destructive testing, subjecting our designs to extreme conditions in order to validate prior analyses and ensure optimal safety and performance.

We have supported various projects through facilitating:

● Frontal Impact Testing

● Seatbelt Anchorage Testing

● Dynamic Roll Over Testing

● Static Roof Crush Testing

● Durability Testing (incl. battlefield mission)

● Falling Object (FOPS) Testing

Testing Standards

Renowned for our extensive expertise in industry specific and international standards, we are committed to ensuring compliance with the latest regulations including:

• Motorsport ROPS (Roll Over Protection Systems) Regulations e.g. FIA, Motorsport UK

• Industrial ROPS Standards e.g. ISO3471, ISO8082

• Industrial FOPS (Falling Object Protective Systems) Standards e.g. ISO3449

• International Oil, Gas & Mining Regulations e.g. BP, Shell, ADNOC

• International Military Standards e.g. Def Stan, MIL-STD, DEF(AUST)

• International Automotive Standards e.g. UNECE, FMVSS, EEC, NHTSA Regulations

Our experience allows us to confidently help our clients navigate the relevant testing procedures, resulting in high quality solutions tailored to meet specific needs.

Safety Devices is the world’s largest, most trusted and experienced roll-over protection designers and manufacturers with over 50 years of experience.

50+ Years

Worldwide solutions

Largest product range

Design Excellence

Quality assurance

Advice & After Sales

FAQs

Which quality standards do you employ?

We are renowned for the quality of our products using only the finest, traceable materials, offering proven capability to fabricate roll over protection in line with various industry standards. To ensure that our products meet the highest standards for a wide range of project needs, Safety Devices are ISO9001 certified.

What are your roll cages made of?

The majority of Safety Devices roll cages are manufactured from E355+N Cold Drawn Seamless Carbon Steel. On a number of our internationally homologated weld in roll cages, we also offer T45 as an alternative material. More exotic materials (Chromoly, 15CDV6, Titanium) can also be used in some applications providing regulations allow, however the material costs of these can be significantly higher than E355+N or T45.

What is a roll cage or ROPS?

A roll cage or ROPS (Roll Over Protection System) is an internal or external structure installed on a vehicle, designed to protect vehicle occupants by preserving survival space during a rollover incident.

Can I buy products directly from Safety Devices?

Yes, well sell directly to companies and other organisations within the Automotive, Fleet, Construction and Military sectors.

Where are Safety Devices products made?

All of our products are supplied through our development workshop and offices located in the United Kingdom, or our dedicated production facility operating out of Poland. These premises are wholly owned and operated by Safety Devices.

Phone+44 (0)1638 713 606

Opening Hours09:00 – 17:00

Monday – Friday

Holborn Ave

Mildenhall

Suffolk

IP28 7AN

United Kingdom